Solaris-Belltec Specialty Augers: Tailored Solutions for Unique Drilling Needs

When it comes to specialized drilling applications, Solaris-Belltec offers a comprehensive range of specialty augers designed to meet the unique demands of every project. Whether you’re planting trees, working with lightweight materials, or require custom pressure tools for heavy-duty operations, these specialty augers provide innovative solutions for precise and efficient performance.

Take a look at these distinct specialty auger types—Tree Augers, Puff Augers, and Custom Pressure Tools—showcasing their unique applications, benefits, and design features.

Tree Augers: Precision for Planting

Tree Augers are specially designed for arborists, landscapers, and agricultural professionals to simplify tree planting. These augers feature a tapered design that creates a smooth, cone-shaped hole ideal for planting saplings or larger plants. By minimizing soil displacement and ensuring even spacing, Tree Augers streamline planting tasks and ensure proper root establishment.

Key Benefits of Tree Augers

- Efficient Hole Design: Creates cone-shaped holes for optimal root development and planting depth.

- Reduced Soil Displacement: Maintains soil integrity around planting sites.

- Versatility: Compatible with a wide range of equipment, including skid steers and excavators.

Tree Augers are perfect for landscaping projects, forestry operations, and agricultural applications, offering reliability and precision to maximize planting efficiency.

48-INCH OAL – DOUBLE FLIGHT – STANDARD DIRT TEETH

| Diameter | 2-in Round | 2.5-in Round | 2-in Hex |

|---|---|---|---|

| 18 | A09027A | A09027B | A09027C |

| 24 | A12027A | A12027B | A12027C |

| 30 | A15027A | A15027B | A15027C |

| 36 | A18027A | A18027B | A18027C |

| 42 | A20027A | A20027B | A20027C |

| 48 | A24027A | A24027B | A24027C |

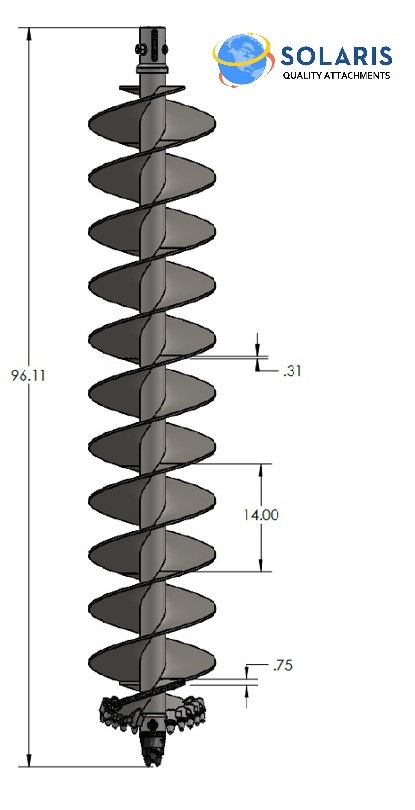

Puff Augers: Lightweight and Effective

Puff Augers are specifically crafted for handling lightweight, displaceable materials such as sand, silt, and clay. With a streamlined design, these augers ensure minimal drag and energy consumption during drilling. They are an excellent choice for contractors working on projects where material removal isn’t a primary concern, but efficient penetration is essential.

Advantages of Puff Augers

- Lightweight Design: Allows for easy handling and low energy consumption.

- Specialized for Loose Soils: Ideal for drilling in sand, silt, or clay without clogging or excessive wear.

- Durable Construction: Built to withstand repeated use in lightweight materials.

Puff Augers are a cost-effective solution for contractors and utility workers who need reliable tools for less demanding drilling tasks.

38-INCH OAL – 2-INCH TUNGSTEN CARBIDE PUFF AUGER

| Diameter | 2-in Round | 2.5-in Round | 2-in Hex |

|---|---|---|---|

| 2 | A02005A | A02005B | A02005C |

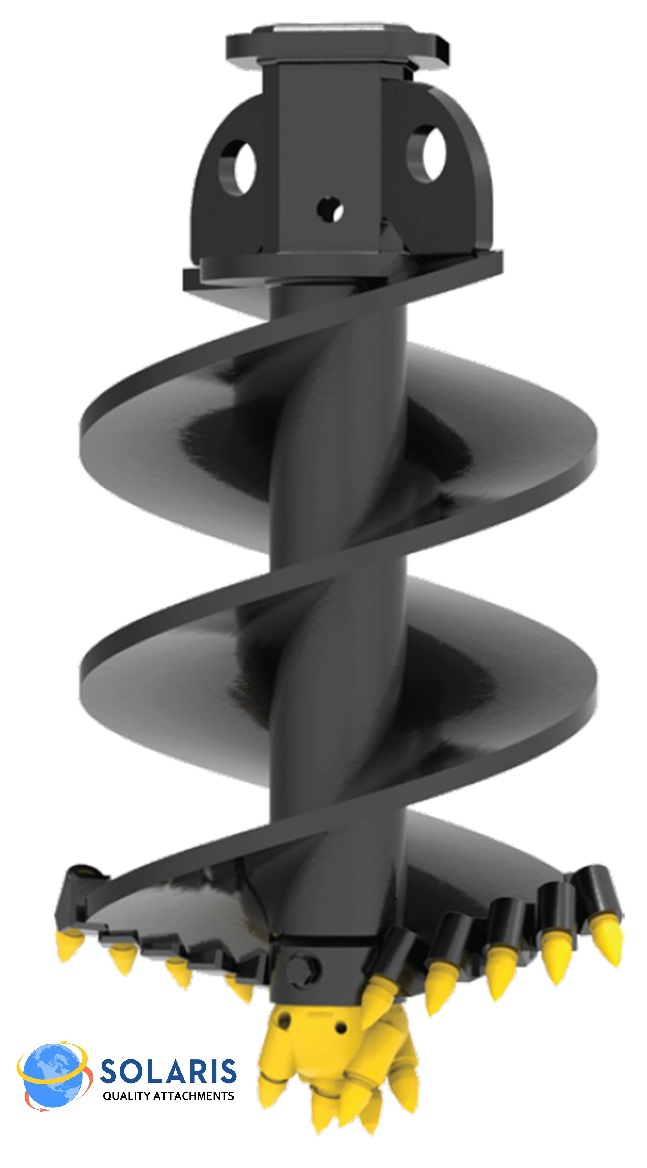

Custom Pressure Tools: Built for Extreme Conditions

Custom Pressure Tools and fully-flighted auger systems from Solaris-Belltec are tailored solutions for heavy-duty and complex drilling applications. Designed to handle the unique demands of specific industries, these custom tools can be fabricated to meet the requirements of any machine, including excavators, skid steers, and Digger-Derrick Trucks. Whether you need an auger for utility pole installations, geotechnical drilling, or foundation projects, Solaris-Belltec can design a tool that delivers optimal performance and durability.

Why Choose Custom Pressure Tools?

- Fully Customizable: Pressure tools and auger systems are designed to your exact specifications, ensuring a perfect match for your machine and project needs.

- Heavy-Duty Performance: Built for extreme conditions, these tools excel in high-pressure and high-impact environments.

- Wide Compatibility: Fabricated for various equipment types, including excavators, skid steers, and trucks.

Applications for Custom Pressure Tools

- Utility Pole Installation: Create stable foundations for poles and pilings.

- Geotechnical Drilling: Perform precise soil and rock analysis for construction projects.

- Foundation Work: Ensure strong and reliable foundations for buildings and structures.

By investing in Custom Pressure Tools, you’re not just purchasing an auger—you’re acquiring a tailored solution engineered to enhance productivity, reduce wear, and deliver reliable results under the most demanding conditions.

Fabrication for Every Machine

Solaris-Belltec takes pride in its ability to fabricate fully-flighted auger systems and pressure tools for nearly any machine type. From small-scale skid steers to large excavators and Digger-Derrick Trucks, every custom tool is designed to integrate seamlessly with your equipment. This ensures compatibility, safety, and maximum efficiency across a variety of drilling applications.

Features of Custom Fabrication

- Precise Engineering: Ensures optimal performance and long-lasting durability.

- Application-Specific Design: Tailored to your unique project requirements, no matter how complex.

- Unmatched Versatility: Fabrication options available for diverse industries, including construction, utilities, and agriculture.

Why Choose Solaris-Belltec Specialty Augers?

Uncompromising Quality

All Solaris-Belltec augers are manufactured with premium materials and advanced engineering techniques, ensuring exceptional durability and performance in every application.

Innovative Design

From the unique tapered design of Tree Augers to the streamlined structure of Puff Augers and the heavy-duty capabilities of Custom Pressure Tools, every product is crafted with the end user in mind.

Comprehensive Support

Solaris Attachments provides industry-leading customer service and warranty coverage, giving you confidence in your investment and peace of mind on the job site.

Find the Perfect Auger for Your Project

When it comes to specialized drilling needs, Solaris Attachments has you covered. Whether you’re planting trees, working in lightweight materials, or tackling complex geotechnical challenges, their specialty augers deliver unmatched precision, efficiency, and reliability.

Explore the full range of Solaris-Belltec Specialty Augers at SolarisAttachments.com. Contact us today to request a quote or call us now at (888) 754-3609 and get expert assistance in choosing the right auger for your specific needs. You can also fill out the quote request form below. Let us help you drill smarter, faster, and with greater precision!